The Role of Augmented Reality in Auto Maintenance Parts Identification and Replacement

Augmented reality (AR) has revolutionized the way auto maintenance is carried out, providing mechanics with a powerful tool to enhance their efficiency and accuracy. By overlaying digital information onto the physical world, AR technology enables technicians to access real-time data about the vehicle they are working on, helping them diagnose issues quickly and accurately. This not only reduces the time needed to identify problems but also minimizes the chances of errors in the maintenance process.

Moreover, AR simplifies complex tasks by providing step-by-step guidance to mechanics, allowing them to follow instructions with precision. This innovative technology enhances the overall workflow in auto maintenance by offering interactive visualizations and detailed information on car components. With AR, mechanics can visualize the inner workings of a vehicle in a virtual space, making it easier to understand the maintenance procedures required and ensuring a smoother repair process.

How Augmented Reality Facilitates Parts Identification

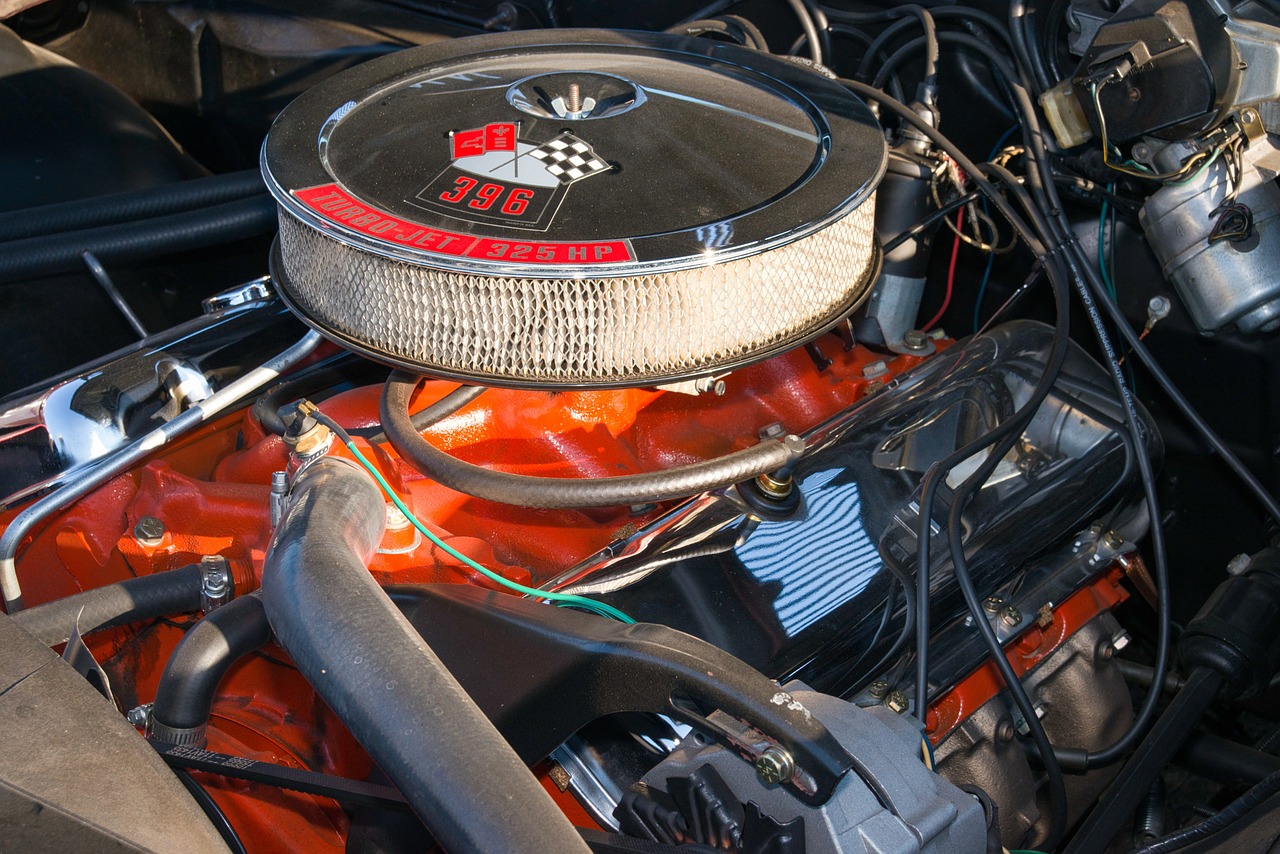

One of the key advantages of utilizing augmented reality in auto maintenance is its ability to streamline the process of parts identification. Traditional methods often involve referring to manuals or searching through physical parts, which can be time-consuming and prone to errors. With augmented reality technology, technicians can simply point their device at a vehicle component and instantly receive real-time information about it.

By overlaying digital data onto the physical environment, augmented reality provides technicians with detailed specifications and relevant instructions for each part. This not only enhances the accuracy of parts identification but also speeds up the overall maintenance process. The immersive nature of augmented reality allows for a more intuitive and efficient way of locating and understanding auto parts, ultimately improving the effectiveness of maintenance tasks.

The Efficiency of Augmented Reality in Replacement of Auto Parts

Augmented reality (AR) has revolutionized the process of replacing auto parts by providing users with a more efficient and accurate way to complete the task. When it comes to identifying and replacing complex components, such as engine parts or intricate electrical systems, AR technology offers real-time guidance and visual overlays that enhance the user experience.

By utilizing AR applications, mechanics and DIY auto enthusiasts can access step-by-step instructions and virtual guides that enable them to seamlessly navigate the replacement process. Instead of relying solely on traditional repair manuals or online tutorials, AR empowers users to visualize the exact location and orientation of each part, resulting in quicker and more precise repairs. This not only reduces the likelihood of errors but also minimizes the time spent on troubleshooting and ensures a smoother replacement procedure overall.